- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Cara nindakake pemotong stainless stainless stainless stainless kanthi potongan laser

2025-03-27

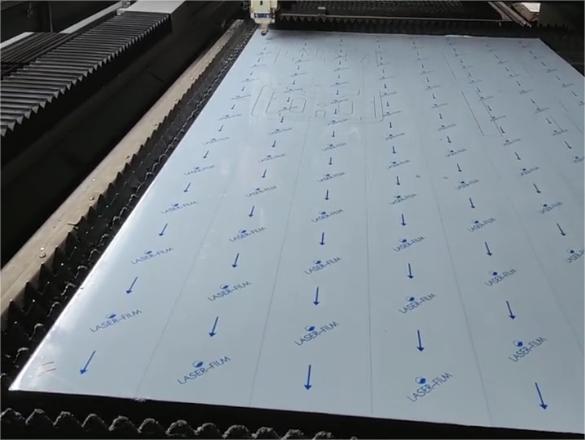

With the increasing demand for high-precision processing in the manufacturing industry, laser cutting technology is becoming more widely used in metal, plastic, and composite materials. Among these, film-covered stainless steel cutting has become an important method for ensuring the surface quality of workpieces, significantly improving machining precision and overall appearance. So, how can film-covered stainless steel be cut efficiently?

What is Film-Covered Cutting?

During the production of metal sheets, a protective film is often applied to the surface to maintain its smoothness. This results in film-covered metal materials, such as window and door components, kitchenware, and stainless steel sheets. The film is applied using high-temperature heat pressing, providing advantages like enhanced corrosion and rust resistance while preventing damage during transportation. Compared to coated plates, film-covered sheets are more cost-effective, widely preferred by manufacturers, and environmentally friendly.

How to Cut Film-Covered Stainless Steel?

To ensure the protective film remains intact, the following steps are recommended:

1. Adjust Cutting Parameters:

Set the laser head at approximately 10mm height.Adjust the power to around 300W for an initial burning process to remove the protective film.Proceed with normal cutting to achieve the best results.

2. Proper Material Placement:

Position the film-covered side facing up to ensure a clean cut. If the film-covered side faces downward, heat and slag from cutting may adhere to the film, making the surface rough and difficult to clean.It is recommended to install pneumatic support on the machine bed to prevent scratches on the sheet.

3. Optimize Airflow Control:

Use nitrogen as an auxiliary gas to prevent oxidation and minimize slag contamination, ensuring a smooth cutting surface.

4.Precision Optical Path Control:

Utilize a high-precision laser optical path adjustment system to maintain clean cut edges and avoid film layer damage due to beam displacement.

Huawei Laser: A Leader in Laser Cutting Solutions

Huawei Laser is committed to providing high-quality laser cutting solutions for customers worldwide, driving innovation and development in the industry.